Automatic Tube Cleaning System also known as Automatic Condenser Cleaning System is an environment friendly system based on inventive technology with the vision of chemical free solution. This advance technology equipment reduces heat transfer effectiveness while providing alleviate fouling and scales deposits on heat exchanger face. For smooth running and maximum effectiveness of chillers this system keeps the tubes free from fouling during chiller in operation.

Automatic Tube Cleaning System is useful in maintaining heat transfer efficiency in cooling towers, water cooled chillers, industries, commercial HVAC System, commercial buildings and many more. ATCS is very cost effective and energy saving environment-friendly system as it is totally harmful chemicals free.

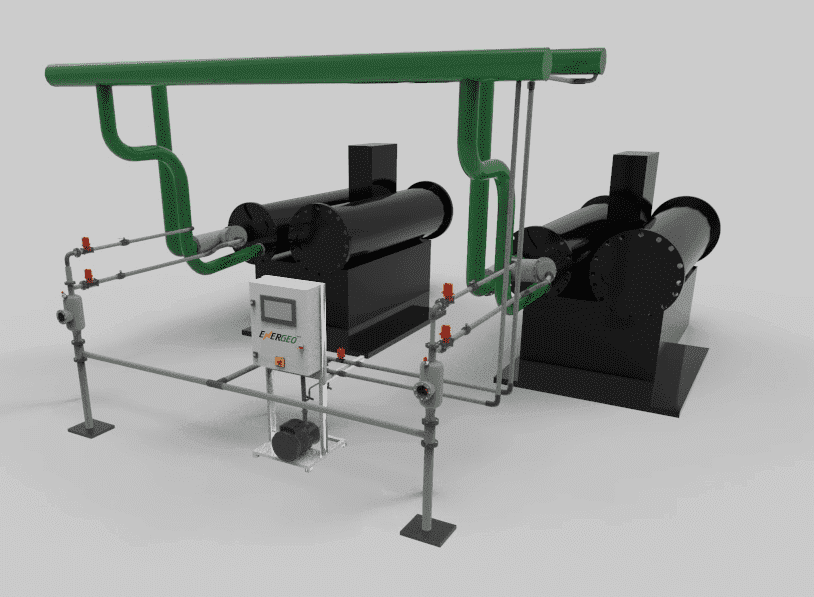

With the use of sponge balls, ATCS keep cleaning the heat exchanger and condenser by periodically injecting into the chiller condenser tube with system flow rate. This removes residue, debris, or any deposits before any fouling results. The tube cleaning process remain continue while the chiller is in operation. This is an automatic system having a regular skid with factory mounted controllers have capacity of multiple condensers cleaning (up to 5) successively.

Benefits of this Automatic Tube Cleaning System :

• ATCS helps maintain heat transfer efficiency and leading to save energy.

• Reduced Equipment Maintenance Downtime

• Help prolonged lifespan for tube based equipment by preventing corrosion and scaling.

• Reduced energy consumption and contributing in energy savings.

• Increases HVAC Chillers's cooling Capacity

• Eliminates offline cleaning completely

• Very cost effective System

The modern technology based ATCS is easy and simple to install and very effective in modern era.